10 Best Wood Lathes of 2024 – Reviews, Top Picks & Guide

-

- Last updated:

Wood lathes are an important tool for all woodworkers, from beginners to the pros. There are no other tools that can do what they can do, but it can be challenging to find a good brand among the many available—and at a few hundred dollars, there is no room for error.

We’ve chosen 10 different brands that are easy to find online and in hardware stores across America. We’ll go over each one’s pros and cons and tell you about any accessories or features they include. We’ve also included a short buyer’s guide to discuss the things you should look for while shopping.

Join us while we take a close look at the center distance, swing, RPMs, horsepower, and more to help you make an informed choice.

A Quick Comparison of Our Favorites in 2024

| Rating | Image | Product | Details | |

|---|---|---|---|---|

Best Overall

|

|

JET JWL-1221VS Variable Speed |

|

CHECK PRICE |

Best Value

|

|

WEN 3421 Variable Speed Mini Benchtop |

|

CHECK PRICE |

Premium Choice

|

|

Powermatic 1352001 3520B |

|

CHECK PRICE |

|

|

|

SHOP FOX W1704 Benchtop |

|

CHECK PRICE |

|

|

|

Delta Industrial 46-460 Variable-Speed Midi |

|

CHECK PRICE |

The 10 Best Wood Lathes

1. JET JWL-1221VS Variable Speed Wood Lathe – Best Overall

The JET JWL-1221VS Variable Speed Wood Lathe is our pick for the best overall wood lathe. It features a powerful motor that can deliver between 60 and 3,600 revolutions per minute (RPMs), adjustable via a control knob, which should be more than enough for most projects. The lathe smoothly switches between forward and reverse at the flip of a switch. The spring-loaded spindle lock makes it easy to change wood projects, and belt tension is easy to adjust with the unique ratchet-style belt tensioning system.

We enjoyed the smooth operation, especially and high RPMs afforded by the JET JWL-1221VS, and we could only complain that it’s a little heavy at 136 pounds, and the motor sits under the headstock, which causes it to collect a lot of shavings and dust. It provides 21 inches between centers and a 12-inch swing.

- 60–3,600 RPMs

- Forward and reverse

- Ratchet style belt tensioning system

- Spring-loaded spindle lock

- 21” between centers

- 12” swing

- 136 lbs

- The motor sits under the headstock and collects shavings and dust

2. WEN Variable Speed Benchtop Wood Lathe – Best Value

The WEN 3421 Variable Speed Mini Benchtop Wood Lathe is our pick for the best wood lathe for the money. The work area is 12 inches long and eight inches wide and is perfect for smaller projects like pens, cups, bowls, and more. The 3.2-amp motor will turn the wood between 750 and 3200 RPMs. The 2.3-inch faceplate, MT1 spindle, and tailstock taper are all durably built, and despite being mostly cast iron, it only weighs 44.9 pounds.

The downside to the WEN 3421, especially when compared to our top choice, is that the RPMs are a little slower, and there’s less variable range in RPMs. We also found that it bogged down easily, so you need to be mindful of your application pressure. It provides 12-inches between centers and an 8-inch swing.

- 12” long, 8” wide

- 2-amp motor

- 750 – 3200 RPM

- 3-inch faceplate, MT1 spindle, and tailstock taper

- 44.9 lbs

- 12” between centers

- 8” swing

- Bogs down

3. Powermatic 3520B Wood Lathe – Premium Choice

The Powermatic 1352001 3520B Wood Lathe is our pick for the premium choice wood lathe. It uses a powerful 6.2-amp 2-HP motor to create up to 3,200 RPM. It includes two interchangeable pullies that you can switch to adjust the RPMs. One pully operates between 50 and 1,200 RPM, and the other between 125 and 3,200 RPM. It’s made of heavy-duty cast iron and provides you with a large 20 x 35-inch work area. A digital RPM meter is easy to read, and it includes several accessories, including a guard, tool rest, faceplate, wrench, knockout rod, and spindle lock.

The Powermatic 1352001 is extremely powerful and never bogs down. You can complete a wide range of projects in the large workspace, and the only thing we can complain about is its extreme 682-pound weight, which makes for a challenging assembly. It provides 35-inches between centers and a 20-inch swing.

- Digital RPM readout

- 2 HP motor

- Heavy-duty cast iron

- Includes several accessories

- 20” X 35”

- Up to 3200 RPM

- 35” between centers

- 20” swing

- 682 lbs

4. SHOP FOX W1704 Benchtop Lathe

The SHOP FOX W1704 Benchtop Lathe features a 12-inch workspace for working on small projects. It has two tool rests for various turning applications. The 1/3 HP engine creates up to 3,200 RPM, and the speed is variable. It’s cast iron construction is durable, yet the entire machine weighs only 52 pounds.

While we were using the SHOP FOX W1704 we felt it was not very powerful, and it would often bog down even when working on small project. Also, the knobs would often work themselves loose from the vibrations. It provides 12-inches between centers and an 8-inch swing.

- 12” between centers

- Cast iron construction

- Two tool rests

- 700–3200 RPM

- 52 lbs

- Variable speed

- 12” between centers

- 8” swing

- Knobs come loose

- Not very powerful

5. Delta Industrial 46-460 Variable-Speed Midi Lathe

The Delta Industrial 46-460 Variable-Speed Midi Lathe features a 1-HP motor that can deliver up to 1,725 RPM that you can adjust using the variable speed controller down to 700 RPM. Different pulleys change the range of RPMs, and the 12½-inch swing is perfect for smaller projects. It weighs about 100 pounds and features a patented belt tensioning system for making quick adjustments.

What we didn’t like about the Delta Industrial 46-460 was that the bed wasn’t completely smooth and made it hard to use the tools in certain areas. It vibrates quite a bit at higher RPMs, and they installed the forward and reverse switches backward. We checked the internet to see if we were the only ones who had a backward switch, but apparently, everyone does.

- 1-HP motor

- 1725 RPM

- 12½” swing

- Variable speed

- Three pully speed ranges

- Patented belt tensioning system

- 97 lbs

- The bed wasn’t smooth

- Vibrates

- Forward/reverse switch wired backward

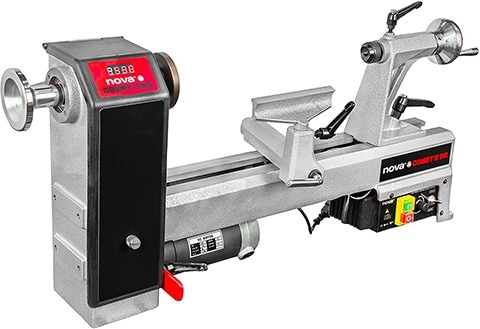

6. Nova 71118 Comet II DR Midi Lathe

The Nova 71118 Comet II DR Midi Lathe uses a ¾ HP motor to deliver speeds between 250 and 4,000 RPM. You can tell exactly how fast the wood is turning by checking the convenient digital readout. 16.5 inches between centers and a 12-inch swing is plenty of room for most small projects, and a forward/reverse switch allows you to use the machine as needed for different projects. The six-inch tool rest is completely adjustable and is an adequate size, and the machine is fairly lightweight at 82 pounds.

The problem we had with the Nova 71118 was that it continuously bogged down with even the slightest pressure, and our digital readout burned out a few months after we got it.

- 250–4,000 RPM

- Digital readout

- Forward reverse switch

- 12” swing

- Five inches between centers

- Six-inch tool rest

- 82 lbs

- Digital readout burns out

- Bogs down

7. RIKON 70-100 Mini Lathe

The RIKON 70-100 Mini Lathe uses a ½-HP motor to deliver between 430 and 3900 RPMs through an easy-access speed change system. There are 16 inches between centers, and it has a 12-inch swing, which should be enough room for all your small projects, including bowl cutting. The self-ejecting tailstock can save time and reduce frustration when you need to remove a center. It’s not too heavy at close to 90 pounds, and you can expand the bed for larger projects.

We felt that the ½-HP motor in the RIKON didn’t have much power, and it bogs down no matter how gentle you are. The speed-changing system isn’t hard, but it does get tedious if you find yourself on a project that requires frequent speed changes. There is also a protective cover that’s loose even though the bolts are tight.

- Easy access speed change

- Self-ejecting tailstock

- 16” between centers

- 12” swing

- 88½ lbs

- 430–3900 RPMs

- ½-HP motor

- Tedious to change speeds

- The protective cover doesn’t close tightly

8. Mophorn 10 x 18 Inch Wood Lathe

The Mophorn 10 x 18 Inch Wood Lathe is an 81-pound machine that can deliver between 760 and 3,200 RPM. It gives you 18 inches between the centers with a ten-inch swing, well suited to creating chair legs and other similar projects. It features 6-inch tool rests for working the wood and the durable cast iron construction will last many years.

The problem with the Mophorn is that it’s very underpowered. They don’t list the horsepower on the package, but we can tell you it bogged down continuously, and we would put it on par with other models that feature an engine under one horsepower. There were also no instructions to help you get started if you are new to using a woodworking lathe.

- 760–3,200 RPM

- 18” between centers

- 10” swing

- Cast iron construction

- Six-inch tool rests

- 81 lbs

- Poor instructions

- Very underpowered

9. PSI Woodworking Turncrafter Commander Midi Lathe

The PSI Woodworking KWL-1018VS Turncrafter Commander Midi Lathe uses a three-quarter horsepower motor to deliver 500 to 3,600 RPMs. It features a wide 18 inches between centers, and a 10-inch swing allows plenty of room for most small projects. The included work light helps illuminate your work area even in low light conditions, and the cast iron base provides a durable platform to work on while remaining lightweight at only 82 pounds.

Like many other models on this list with little horsepower, the PSI Woodworking KWL-1018VS tends to bog down on all but the smallest jobs. There are no instructions included with the purchase, so it is not the tool for the inexperienced user, and there is no reverse switch, which is provided on many other models. While we liked the idea of the work light, but the shade was too small, and most bulbs stick out, causing glare instead of improving visibility. The shade also collects sawdust, which can lead to a fire hazard.

- 500–3,600 RPM

- 18”between centers

- 10” swing

- Includes work light

- Cast iron base

- 82 lbs

- ¾ HP motor

- No instructions

- The work light is too small

- No reverse switch

10. Grizzly Industrial H8259 Benchtop Wood Lathe

The Grizzly Industrial H8259 Benchtop Wood Lathe is the last wood lathe on our list to review for you. This machine is fairly lightweight at just 77 pounds, and it can deliver speeds between 826 and 3,337 RPM. You have 18 inches between centers to fit your wood and a 10-inch swing.

The Grizzly Industrial downside is that there is not enough horsepower to run without continuously bogging down. This model also gets extremely hot in just a few minutes, even when using it at moderate RPM. And you have to adjust the belts to change speeds, which is easy enough but gets tedious if you must change it several times.

- 18” between centers

- 10” swing

- 826–3,337 RPM

- 77 lbs

- ½ HP

- Motor gets hot

- Tedious to change speeds

Buyer’s Guide – Picking the Best Wood Lathe

The wood lathes can look like a complex intimidating machine, but it’s really not that complex, and there are only a few key components you need. Let’s look at a few important things to look for while you shop for a wood lathe.

Horsepower

The horsepower the engine produces is the heart of the machine. You can change speed with pulleys and other methods, but horsepower is responsible for the torque, and without enough torque, your project will continuously bog down when you press your tools against it.

Unless you are going to limit yourself to creating pens and pencils, we highly recommend a lathe with at least one horsepower to provide enough torque for the project.

Distance Between Centers

The centers hold your wood in place, and the distance between them tells you how long your wood can be. Most of the tools on this list have a distance between centers of about 16 inches, but it can vary considerably—and in some cases, you can also extend it by adding additional pieces to the lathe.

Since a larger distance between centers means you can tackle a bigger project, we recommend getting the biggest you could find. If you know you only want to create smaller objects, like ink pens or chess pieces, then the shorter distance between centers may be in order.

Swing

Swing refers to how wide your wood can be when it’s mounted on the centers before it bumps the table. Like the distance between centers, a larger swing value means you can tackle a larger project, so try to get the biggest you can afford, unless you know you won’t need it.

RPMs

In most cases, high RPMs will result in a faster workflow and a smoother finish. If it doesn’t move fast enough, the tools won’t cut well, and they could grab the wood, causing chips. Higher RPMs are always better, but make sure added horsepower is also part of the deal.

Variable Speed

The ability to change speed is a critical part of how a wood lathe works, and there are several methods for changing the speed—including dials, changing pulleys, or adjusting the tension. We found that dial adjusting speed is the best way to go because it’s the easiest, and you can often do it in real-time. The other methods are not difficult, provided you have proper instruction, but they are better suited to projects that remain at the same speed long term.

Reverse Direction

While many models don’t offer it, reverse direction can offer the user quite a bit of flexibility, especially when sanding or cleaning up your work. In most cases, a flip of the switch is all that’s required to reverse direction.

Weight

One more thing you might want to consider before you purchase a wood lathe is how much it weighs. While most of the models on this list are under 100 pounds, others can exceed that by many times. It’s not uncommon to purchase one of these machines only to find out later you need to put it together by yourself. Always make sure you can manage the weight, especially during assembly before purchasing the lathe.

Conclusion

When choosing the best wood lathe for you, we recommend something with high RPMs and plenty of room between centers. Our choice for the best wood lathe, the JET JWL-1221VS Variable Speed Wood Lathe, delivers both with 21-inches between centers and a powerful motor that can reach up to 3,600 RPMs. We didn’t experience any bogging down, and the engine remained cool throughout our projects. The WEN 3421 Variable Speed Mini Benchtop Wood Lathe is another great choice for those looking for a less expensive model to get them started with smaller projects. The engine still packs plenty of power, and at 55 pounds, you can almost consider it portable.

We hope you have enjoyed reading over our reviews and found them helpful for choosing your next wood lathe. If you think it can help others, please share this guide of the best wood lathes on Facebook and Twitter.

More buying guides like this:

- Which mini & midi lathe do we like the most? Find out here

- Metal lathe showdown: which ones are our favorites?

- Wood planer buyer’s guide

- 7 Best Wood Lathe Chucks

Contents