4 Best Mini Mills of 2024 – Top Picks & Reviews

-

- Last updated:

Despite their practicality and convenience, owning a conventional milling machine is out of reach for most people due to the hefty price tag. It is rare to find a good milling machine that costs less than five figures.

Fortunately, you can get a smaller version of milling machines at a much more reasonable price. They are known as mini milling machines or mini mills. Mini mills allow you the convenience of having your own milling machine. While they are still as practical as their larger cousins, the difference comes in the amount of workload that they can handle.

Nonetheless, mini mills vary in size, weight, power, and price. As such, you need to evaluate the various mini mills on the market to find one that suits your needs best. To save you the hassle, we have compared numerous products to bring you these reviews on the best mini mills to consider today.

A Quick Comparison of Our Favorites

| Rating | Image | Product | Details | |

|---|---|---|---|---|

Best Overall

|

|

Grizzly G0704 Mini Milling Machine |

|

CHECK PRICE |

Best Value

|

|

Proxxon 37110 Portable Mill |

|

CHECK PRICE |

Premium Choice

|

|

JET JMD-18 350018 Mini Mill |

|

CHECK PRICE |

|

|

|

WEN 33013 Single Phase Compact Benchtop Milling Machine |

|

CHECK PRICE |

The 4 Best Mini Mills – Reviews 2024

1. Grizzly G0704 Mini Milling Machine – Best Overall

If you are looking for a reliable machine without having to break the bank, the Grizzly G0704 is worth serious consideration.

While not as large as some other mini mills out there, the Grizzly G0704 is not small either. With a table measuring 26⅝ x 7⅛ inches, it offers you enough space to work on substantial projects. The spindle to table distance is a respectable 13 inches with a 15-inch swing. The head has an 11-inch travel allowance and can tilt 90 degrees to either side. You will also appreciate the 6⅞ inches of cross travel and 18⅞ inches of longitudinal travel.

The G0704 comes with a safety shut off to allow you to cut power abruptly in case of an emergency. Additionally, the spindle is fitted with a guard to allow you to go about your job without being on edge all the time.

When it comes to performance, few mini mills rival the G0704 thanks to its 1-HP motor that offers enough to power to handle most milling projects with ease. Additionally, this unit comes with a 2-speed gearbox to allow for forward and reverse functions. Flipping between these two settings is easy, as all you have to do is simply press a switch.

To give you more control over your project, as well as the machine, the G0704’s spindle speeds range from as low as 50 RPM to as high as 2,250 RPM. This allows you to fine-tune the machine to meet the needs of your current project.

And that’s not all.

The Grizzly G0704 features an open-end design to allow for customization. For example, you can even convert it to a computer numerical control (CNC) mill in case you want to use it for an advanced project. You can also adjust its motor if you wish to.

A few drawbacks include its zero setting dials that only display in inches. Therefore, if you are using metric measurements, you will need to keep a notebook nearby for calculations. It also does not come with a vise.

Nonetheless, the Grizzly G0704 is a great mini mill that provides you with the perfect blend of the 3Ps; power, performance, and precision. While it may not be large enough to fulfill a commercial shop’s needs, it is more than excellent for small shops or home craftspeople looking for a reliable mill without having to take out a loan to get it.

You will also appreciate the fact that it comes with a stand, which is typically a bonus accessory when it comes to mini mills, thus saving you extra costs.

- Easy to use, making it ideal for beginners

- Powerful 1-HP motor

- 2-speed gearbox for forward and reverse functions to enhance versatility

- Sturdy build

- Comes with a stand

- Attractive price

- Does not come with a vise

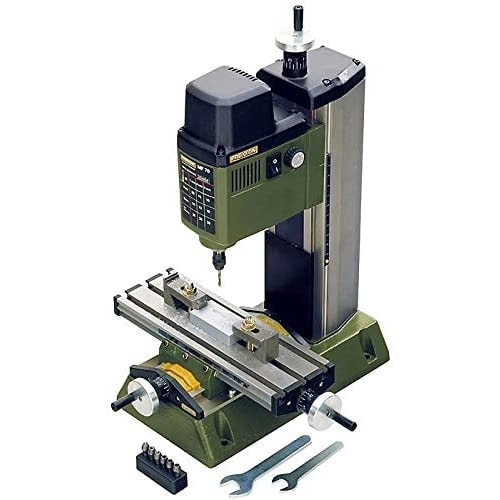

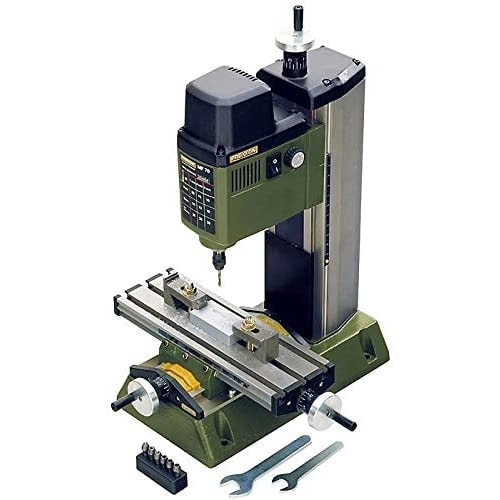

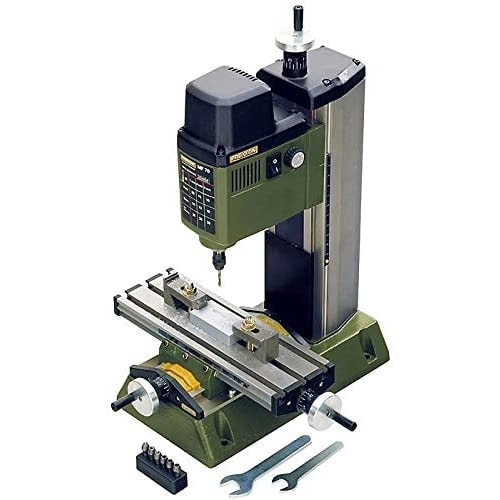

2. Proxxon 37110 Portable Mill – Best Value

If you are willing to downsize a bit to get a high quality mill on a budget, look no further than the Proxxon 37110. While this is a small unit, even by mini mill standard, it makes up for it in performance.

This unit comes with a ⅛-HP motor. Right off the bat, if you are looking for a mini mill that can handle heavy-duty materials or projects, the 37110 is not for you. However, if what you want is something to handle intricate projects, it does not get better than this.

It comes with a variable speed setting to allow you to drift between 5,000 and 20,000 RPM seamlessly. This allows you to fine-tune the mill to meet the needs of your specific project, resulting in superior quality of work.

Durability, reliability, and precision are other hallmarks of the Proxxon 37110. Thanks to a base featuring a cast-iron construction, this unit is unbelievable stable during operation, which allows you to make precise cuts. The headstock, column, and table, on the other hand, are made from treated aluminum, meaning that this unit can take a beating.

As mentioned, this is one small unit, as its table measures 7⅞ x 2¾ inches. This further emphasizes the fact that this mill is designed for intricate high precision projects. Nevertheless, its small size comes with the benefit of portability, weighing only 16 pounds, which is almost unheard of in mills.

Unfortunately, despite its sturdy cast-iron base, the Proxxon 37110 can vibrate significantly during operation. While it does not vibrate as much as larger units do, the 37110 is designed for intricate projects, meaning that even the slightest vibration can affect precision significantly. The other drawback is its inability to handle larger projects. For those reasons, this mill could not make top pick.

Nevertheless, this micro mill is almost perfect, as it is versatile, powerful for the tasks it is intended for, and extremely durable. As such, it would make a great addition in a shop that deals with small components that need to be milled, such as a jewelry store or an optician’s shop.

Moreover, it comes at an extremely friendly price point. Considering its high-quality design and construction, the Proxxon 37110 is one of the best mini mills for the money.

- Cast-iron base for stability and durability

- Durable-treated aluminum construction

- ⅛-HP motor that delivers enough power for intricate projects

- 5,000 to 20,000 RPM variable speed for greater control

- Adjustable scale

- Portable thanks to weighing only 16 pounds

- 2-year limited warranty

- Too small for large-scale projects

- Vibrates significantly

3. JET 350018 Mini Mill – Premium Choice

The JMD-18 by JET is a beast of a milling machine that also doubles as a drilling press. If your budget allows it, you should consider the JMD-18, as it is arguably the best mini mill in production today. It is ideal for both metal- and woodworking, as well as both light-duty and heavy-duty purposes.

One of the main reasons we love the JMD-18 is its user-friendliness. Milling machines have a reputation for requiring lots of experience to operate That is not the case with the JMD-18. This mill comes with stylish easy-to-read dials, thus ensuring that your measurements are on point at any time. The same goes for the depth gauge, thanks to its straightforward nature; it allows you to be consistent in your cuts. What’s more, the head can swivel a full 360 degrees, allowing you unlimited flexibility hence enhancing your versatility.

When it comes to performance, you will be hard-pressed to find a mini mill that can rival the JMD-18, thanks to its single-phase 2HP UL-listed motor. This powerful motor allows the mill to handle just about any type of material without over-exerting itself.

Additionally, the JMD-18 boasts 12 spindle speeds spaced out between 15 and 3,000 RPM. This allows you more freedom in the type of projects that you can take on, as different materials require different spindle speeds. What’s more, switching between spindle speeds should not be an issue, thanks to the quick action latch on the hinged belt cover. It allows you to switch speeds in seconds, thus improving your efficiency.

It would be a loss if such a powerful machine would not be able to take on large workpieces due to size constraints. Luckily, it does, thanks to its spacious worktable measuring 31¾ x 9½ inches. The JMD-18 features a 1¼-inch drilling capacity with a 15⅞-inch swing, providing you with a lot of room for drilling. The full spindle distance is 18 inches.

To add to its practicality, the table is equipped with a work lamp to allow you to work even in dim conditions.

Durability and reliability issues are almost unheard of in the JET JMD-18. This beast features cast-iron construction to ensure both stability and durability, which are both hallmarks of a reliable machine.

We were disappointed to find out that this mini mill weighs over 700 pounds and does not come with a stand. Nonetheless, as compensation, the manufacturer provides you with a vise and carbide face mill.

All in all, the JET JMD-18 is as close as it gets to acquiring a conventional industrial-grade milling machine without the monstrous price point. As such, it can be used for both DIY and professional use. Couple that with the fact that it also doubles as a drilling press, its premium price begins to look like a bargain.

- Doubles as a drilling press

- Powerful 2-HP motor that can handle most applications with ease

- Durable and stable cast-iron construction

- Large worktable measuring 31¾ x 9½ inches

- Equipped with a work lamp for use in dim conditions

- User-friendly

- Heavy at 700 pounds

- Costly

4. WEN Single Phase Compact Benchtop Milling Machine

The WEN 33013 might not be as powerful as the JMD-18 by JET, but it is worth considering if you are looking for a reliable mill with reasonable power and decent performance.

This unit comes with a 4.5-amp motor with variable speed for greater control and precision. In the low setting, it runs between 100 and 1,100 RPM and between 100 and 2,500 RPM when you set it high.

With dimensions of 18.1 x 4.75 inches, the WEN 33013 has sufficient room on its table for most applications. Moreover, it has an 11.8-inch longitudinal table travel and 5.1-inch vertical travel to allow you reasonable working space. The head can swivel 45 degrees on either side, allowing you some flexibility.

Nonetheless, this unit might not be the best performer out there due to limitations in design and power. However, it is worth checking out to see whether it can meet your needs.

- Average power and performance

- 2-year warranty

- Limited versatility

Buyer’s Guide – Purchasing the Best Mini Milling Machine

A mini mill is a significant investment, with most costing thousands of dollars. Therefore, you want to be careful when making this type of decision to avoid investing in a mill that does not meet your needs.

The following are some of the most important factors to consider when choosing a mini mill.

Brand or Manufacturer

Products from reputable brands, on average, cost more than those from lesser-known manufacturers. While any manufacturer can make an excellent mill, we have found that lesser-known brands tend to create poor-quality tools. This can be attributed to their limited financial resources.

As such, we recommend checking out a mini-mill from a reputable manufacturer first before you start considering other options. If a product from a relatively unknown manufacturer entices you, ensure that you practice due diligence to avoid making a bad investment.

Size

Even though a tiny mill might seem like a good idea-especially due to lower pricing, it is more than likely not going to meet most of your milling needs. Moreover, a small mill limits the array of projects that you can take on. It is also worth mentioning that tiny mini-mills cannot take a prolonged beating, meaning that their durability is questionable.

Nonetheless, if you are looking for a mill for light-duty wood projects, purchasing a beast of a mill would be pointless.

When it comes to size, consider purchasing the largest, heaviest, and most rigid unit you can find with your budget. This is because a heavy unit gives you a sturdy base, hence enhancing your accuracy and precision. Additionally, a larger size allows you to work with larger workpieces, thus broadening the scope of projects that you can take on.

Power & Speed

The type of material that you will be working on will determine the amount of power you require of a mini mill. If you are planning to mill steel, you will require a powerful machine with high horsepower, as well as adjustable speed. This is because steel isn’t easy to handle.

However, if you are working with less difficult materials such as brass, aluminum, wood, or composites, you can get away with a unit with lesser horsepower.

As a rule of thumb, if your projects revolve around working with malleable materials or miniature work, a mill around ⅛-HP would suffice. However, if you are working on more intense jobs, look for a unit with 1-HP or more.

Speed matters, too, as the ideal rate varies between materials. Therefore, you want a machine with variable speed, as it will allow you to fine-tune the spindle speed to match your project’s requirements. Mills with pre-set speeds across their RPM range are great too. The best are those that come with numerous pre-sets.

Vibration

You cannot be accurate if your base is not sturdy. Therefore, if the motor’s vibrations can be felt on the mill’s base, it is highly unlikely that you will be able to take on intricate projects. As such, if accuracy means a lot to you, look for a unit whose base is sturdy enough to tolerate vibrations.

Cast iron is the best material for mini-mill base. It absorbs the vibrations to allow you a sturdy base while being extremely durable. This means that a mill featuring a cast iron construction is likely to be around for a long time.

Flexibility

You want a mill that is flexible enough to allow you to cut at complex or unorthodox angles. This flexibility comes from the head. Look for a unit with a head section that can tilt and rotate. Some mini mills’ heads tilt a mere 45 degrees to the left or right, while others can tilt a full 360 degrees.

More buying guides like this:

- A closer look at benchtop milling machines – which one suits you?

- Chainsaw mill showdown: see the winner & our budget picks

- Router lift buyer’s guide & top picks

Conclusion

A mini-mill would make for an excellent addition in any workshop. It allows you to make all kinds of shapes from tough or difficult materials. Nonetheless, these machines are incredibly expensive, meaning that you need to do due diligence before making such a purchase. Fortunately, reviews such as this one should help you make the correct choice.

The G0704 by Grizzly is arguably the most well-balanced mini-mill on the market today. It is powerful, large, and versatile. Moreover, considering its stellar attributes, it features an attractive price point.

If you are on a budget, consider the Proxxon 37110. Even though small and inexpensive, this mini mill features a great design and quality construction. It is ideal for light-duty projects.

Contents