10 Best Wood Planers of 2024 – Reviews & Top Picks

-

- Last updated:

What if your home was missing one of the most valuable tools? A wood planer is a “must-have” for every home, especially if you like to work on many projects around the house. Unfortunately, many people don’t have a wood planer and don’t know where to start when it comes to buying one.

You may think, “Who has the time to research the various models?” The answer is us, of course! We’ve scoured countless reviews online to help you find the best wood planer. So which ones are worth your time, and which should you skip? With our in-depth reviews of each wood planer, you’ll finally have your answer!

A Quick Comparison (updated in 2024)

| Rating | Image | Product | Details | |

|---|---|---|---|---|

Best Overall

|

|

DEWALT DW734 Benchtop Planer |

|

CHECK PRICE |

Best Value

|

|

TACKLIFE TGGLA152 Electric Hand Planer |

|

CHECK PRICE |

Premium Choice

|

|

Delta Power Tools 22-590 Portable Planer |

|

CHECK PRICE |

|

|

|

WEN 6552T Benchtop Corded Thickness Planer |

|

CHECK PRICE |

|

|

|

Makita 2012NB 12-Inch Planer |

|

CHECK PRICE |

The 10 Best Wood Planers

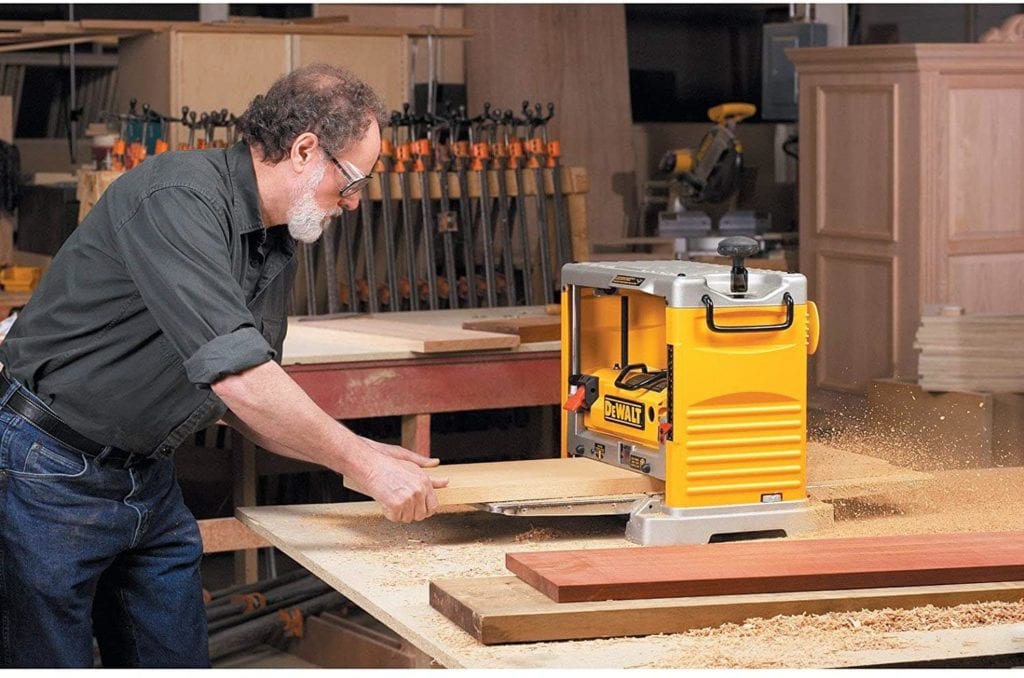

1. DEWALT DW734 Benchtop Wood Planer – Best Overall

The DEWALT DW734 Benchtop Planer is our overall top pick for wood planers. It’s one of the more high-end options available, but you definitely get what you pay for!

Power and speed are the main hallmarks of this planer. It has a powerful motor that powers a 10,000 RPM cutting-head speed, allowing the planer to make 96 cuts per inch.

Keep in mind this is not the planer for beginners. You’ll need to monitor the infeed and outfeed foldouts so they remain level, and you may need to replace short screws with longer bolts for maximum stability.

- Available with and without knives.

- Reduced movement and increased stability

- Powerful motor and fast speeds

- Long-lasting knives

- Expensive

- Not easy to use for beginners

- Very heavy

2. TACKLIFE TGGLA152 Electric Hand Planer – Best Value

You may not want to buy the biggest and most expensive wood planer. If you’re more interested in the best wood planers for the money, the TACKLIFE TGGLA152 Electric Hand Planer is our pick for the best value.

It’s tough to beat the price on this model, and you get a lot of features for your money. This includes a solid power-to-weight ratio (6-amp/16,500 RPM @ 6.93 pounds) and a surprisingly high degree of accuracy.

Why isn’t the Tacklife our number-one pick? In addition to offering fewer options, you are likely to experience issues with the leveling surface and maintenance.

- Very affordable

- Plenty of power

- Accurate cuts

- Reversible blades

- Mediocre leveling surface

- Hard to replace blades

- Limited potential

3. Delta Power Tools Portable Planer – Premium Choice

Planers are available in a variety of lower-end and higher-end options. If you are looking for the best of the higher-end options, then it doesn’t get better than the Delta Power Tools 22-590 Portable Planer.

What do you get for the luxury price tag? This planer reduces snipe thanks to the cutterhead lock system and the well-designed infeed and outfeed table. The machine is also very versatile, allowing you to choose precise dimensions for your subsequent cuts.

It’s not all great news, though. It’s surprisingly easy to burn the belt out, and it may require adjustments right out of the box for you to get the most out of it.

- Versatile three-knife cutterhead

- Very fast

- Secure cutterhead lock

- Belt can burn out easily

- Belt alignment issues

- Knives easily wear out

4. WEN Benchtop Corded Thickness Planer

While it’s not the absolute best for the money, the WEN 6552T Benchtop Corded Thickness Planer is one of the best value picks on this list. With its 15-amp motor, you can generate 25,500 cuts per minute with a smooth rate of 26 feet per minute.

The three-blade design has a lot of potential, and we like that the fan-aided dust port makes it easy to breathe. Unfortunately, this system is likely to make a mess for you to clean up, so you’re trading one annoyance for another.

- Speedy feed-rate

- Solid price

- Versatile three-blade cutter

- Easy to adjust depth

- Bad dust collection system

- Weak bearings

5. Makita 2012NB 12-Inch Wood Planer

The Makita 2012NB 12-Inch Planer is another high-end option for your wood planer needs. Interestingly, this model (at a modest 60 pounds) offers a good combination of compact design, portability, and project versatility.

This is also one of the quieter planers on this list, clocking in at about 83 dB. While that’s still quite audible, it is quieter and unobtrusive compared to most planers. And despite keeping quiet(er), this planer is very fast, allowing you to plane up to 28 feet per minute.

What we don’t love is the price. You can get most of the features in this planer at a lower price point. And if you’re willing to shell out for premium prices, other premium planers offer more bells and whistles.

- Portable and compact

- Relatively quiet

- Super fast

- Convenient table extensions

- Expensive

- Not enough features for the price

6. PORTER-CABLE PC60THP Hand Planer

Some planers are designed as fixed models, while others have portability in mind. If you specifically need a portable planer, the PORTER-CABLE PC60THP Hand Planer is the way to go.

At 8.5 pounds, you can take the planer just about anywhere. Even if it doesn’t go beyond your house, it’s easy to set up in any position. Fortunately, the aluminum shoe provides the strength and stability you need without weighing the planer down. And there is a convenient knob to make depth-adjustment a breeze.

There are limitations to the small size and portability. For example, the Porter-Cable planer lacks the range of other models, and the finish it provides is not as refined or precise as other models.

- Very lightweight

- Convenient depth-adjustment

- Dual dust extraction feature

- Some quality control problems

- Front-hand grip depth-adjustment can lead to planing mistakes

7. CRAFTSMAN CMEW320 Benchtop Planer

What if you’d prefer a more “midrange” option? In that case, the CRAFTSMAN CMEW320 Benchtop Planer is a very solid pick. We were impressed by the 8,000 RPM head, which allows you to make up to 16,000 cuts per minute. And the two-knife steel head provides a smooth planing experience while helping your equipment last much longer.

However, setting the Craftsman planer up can be difficult, especially if you’re inexperienced. And the gauge can make it difficult to get the exact depth you need without adjustments or modifications.

- Smooth operation

- Easy dust collection

- Great for both hard and soft wood removal

- Difficult to set up

- Not as many features as other models in this price range

8. POWERTEC Amp 2-Blade Benchtop Wood Planer

The POWERTEC PL1252 15 Amp 2-Blade Benchtop Planer is impressive at first. It has a relatively low price for a full-size planer. Unfortunately, you’ll quickly notice why this model is near the bottom of our list.

Planing on this model takes a very long time for everything except the tiniest pieces of wood. While the two-knife cutterhead can get the job done, it doesn’t offer the versatility or precision of the three-knife models.

You’re also going to experience snipe issues more often than not. In other words, this cheaper model will cost you a lot in terms of time wasted fixing various issues.

- Low cost

- Very Lightweight

- Snipe problems

- Two-knife cutterhead

- Disappointing depth

RELATED: we also have an article where we go over the best electric hand planers

9. Grizzly Industrial G0505 Benchtop Planer

With the Grizzly Industrial G0505 Benchtop Planer, you are moving towards the higher end of planer prices. Unfortunately, it does not offer the performance or features you might expect from a planer at this price point.

To its credit, this lightweight planer is nice and fast (32 feet per minute). Sadly, the two-blade cutterhead is less efficient and versatile, and it will inevitably cause your machine to burn out more quickly.

That limited cutterhead will also affect how deeply you can cut into the wood without problems. And when you’re willing to pay for a planer in this price range, you’re better off buying something much better.

- Very fast

- Relatively accurate

- Limited two-blade cutterhead

- Bad depth of cut

- Not enough options or performance for the price

10. Cutech 40200H-CT Spiral Cutterhead Planer

Want to see a visual definition of the word “compromise?” In that case, look no further than the Cutech 40200H-CT Spiral Cutterhead Planer. It’s not the worst planer in the world, but it’s a planer that doesn’t have a true audience. For example, it’s not a pro planer because you can get more features for a lower price from other models.

Also, it’s not great for beginners due to the price. It weighs 90 pounds, which is hardly portable for trucking between job sites. The spiral cutterheads are a nice touch, and the dust port is convenient. But you should check out other planers for better prices and more features.

- Spiral cutterheads are great

- Built-in dust port is convenient

- Very expensive

- Neither sturdy nor very lightweight

- Extremely noisy

Buyer’s Guide: How to Choose the Best Planer

Now that you’ve read the reviews, you should have a better idea about the best planers. However, even after you narrow things down to a few possible choices, it can be difficult to finalize your decision.

That’s where our buying guide comes in. With this guide, newbies and veterans can learn about the factors and features that will help you purchase the best wood planer.

Hand Planers: The Right Choice?

You probably know from our reviews that some planers are light enough to work as hand planers. Others are meant to be used as stationary devices. How, then, can you decide whether you need a hand planer?

The main thing hand planers have going for them is their weight. If you’re traveling and need to bring a planer with you, they are almost always your best bet.

With that being said, hand planers don’t provide the level finish that other planers do. This is usually because of the lumber’s uneven surface and the potential for user error.

If you need something more level and steadier, you need a traditional planer (a thickness planer). Some planers (usually pro planers) are effectively stationary because they weigh hundreds of pounds. Other planers are lighter but designed as benchtop models that can remain stationary as you work.

It’s easy to get confused about “portable” vs “hand planer.” Portable may refer to any planers you can pick up and move, including most benchtop models. Hand planers are specifically meant to be used as handheld devices.

So, when should you use a thickness planer over a handheld planer? They help you set the blade at a particular height and shave everything above that point. So, if you need a more consistent level surface or just want to save yourself some elbow grease, you should use traditional planers instead of hand planers.

Cutting Depth

You can cut nearly as deep as you want with a hand planer. You simply have to worry about the limitations of your device and your physical energy. With thickness planers, you can decide how much you want to cut per pass. This gives you finer control of everything, but you must worry about making multiple passes if the wood is thick enough.

The model you are using determines how much you can remove per pass. For example, 1/16 inch is the industry standard. But some fancier (and more expensive) models allow you to double that and cut 3/32 inches per pass.

While you pay for the privilege of that increase, it does effectively cut the number of passes you have to make in half. This can be especially important if you are working on a large project and time is of the essence.

Remember that “deeper is not always better” when it comes to cuts. A deep cutting depth can more easily lead to unwanted tear out, especially on wood that is very soft or very hard. Finding the cutting depth that is best for you and your material may take some trial and error.

Risk of Snipe

We’ve mentioned unwanted snipe a few times now. But what is snipe? It’s when the board you are cutting gets pulled into the blade a bit too early, resulting in a piece of wood that is unevenly cut and looks awful.

As long as the wood in question makes it to the second roller on the planer, the snipe risk goes away entirely. Unfortunately, it’s easy for snipe to happen on some models versus others.

If you’re worried about snipe, look for planers that offer ways to reduce the risk. A planer that allows you to adjust the tables will let you mitigate this risk. And you can manually switch the planner to smaller cuts towards the end, as this serves to greatly reduce the risk of snipe.

Cuts Per Inch

Some planers (but not all) will allow you to adjust cuts per inch. You generally want a higher CPI rather than a lower one. It reduces the chance of sniping and tearing out while minimizing the size of the hills and valleys you create by cutting.

What if the manufacturer does not advertise the CPI rate? In that case, you can do quick “back of the napkin” math to determine the rate. Start by multiplying the number of blades by the overall RPG of the cutterhead. Next, multiply the feed rate by the accepted lumber width (normally 12 inches). Now, you can simply divide the first number by the second to determine CPI.

Most people will be fine with a CPI of 90 or higher, but you may want it higher to be on the safe side.

Dusty Work

Some models have dust collection features, and others do not. If you’re worried about dust, do your homework on a planer before you buy it. You’ll want a dust collection port that is between 2.5 and 4 inches, ensuring maximum coverage with your other dust collection devices.

If you already have dust collection devices, make sure to get a planer that matches. This will save you a lot of time and effort and help remove unwanted dust from the area.

Related buying guides you should check out:

- Budget planer showdown: which one to choose?

- WEN 6550 vs 6552 Planer: What are the differences?

- Wood lathe product showdown

- Wood router product showdown – see the winners!

In Conclusion

With any luck, our reviews helped you make the best decision for your projects. Speaking of the reviews, which models were the big winners? For the best overall model, we must hand it to the DEWALT DW734 Benchtop Planer. It has most of what you need, and you get what you pay for.

If you’re on a strict budget, we recommend the TACKLIFE TGGLA152 Electric Hand Planer. It’s easy to use, very portable, and it won’t break the bank, making it an excellent choice for beginners. Ultimately, all we can do is shine a light on these different planers. Only you can choose the one that is right for you!

Featured Image Credit: Amazon

Contents