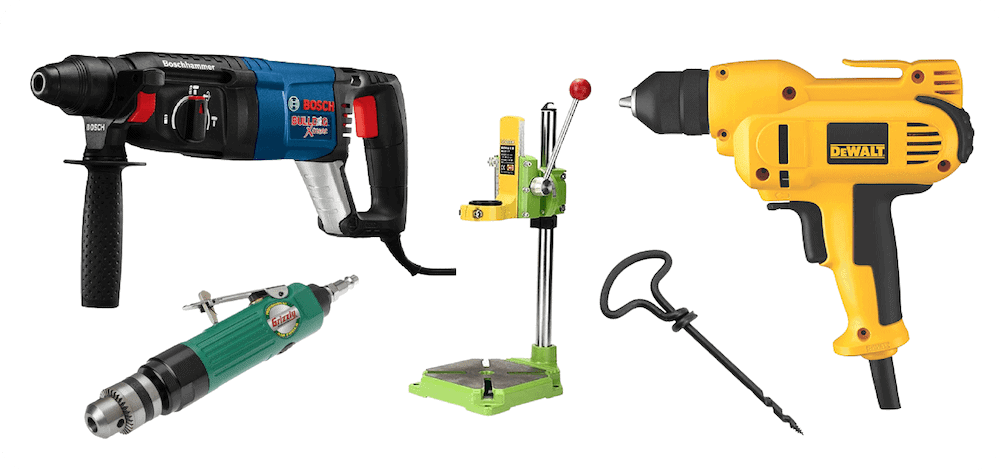

30 Different Types of Drills & Their Uses (with Pictures)

-

- Last updated:

Having the appropriate tools for the job is the first step to producing quality work. Regarding drills, they vary considerably in size, function, speed, and power. Therefore, before you set out to buy one, it is crucial to educate yourself about the various types and their uses to make an informed choice. The following are the most common types of drills and their uses.

Manual Drills (Best for Home Use)

Manual drills were the first type to be created. They convert the circular motion you create physically into amplified torque to allow you to drill holes into hard surfaces. Even though manual drills are not as popular as they once were—due to the physical effort they demand—they are valuable tools to have around the house in case of a power outage. They include:

1. Eggbeater Hand Drill

This gear-driven drill has a driving wheel, which spins when you rotate the handle. Once the wheel starts spinning, the drill moves with the chuck, causing the bit to rotate. This manual tool is adept at making smaller holes in wood and metals.

2. Breast Drills

Breast drills function like eggbeater hand drills; the only difference is that they come with a plate attached to their back. The plate allows you to apply more drilling pressure by pressing your chest against the drill. It makes the breast drill more powerful than eggbeater hand drills.

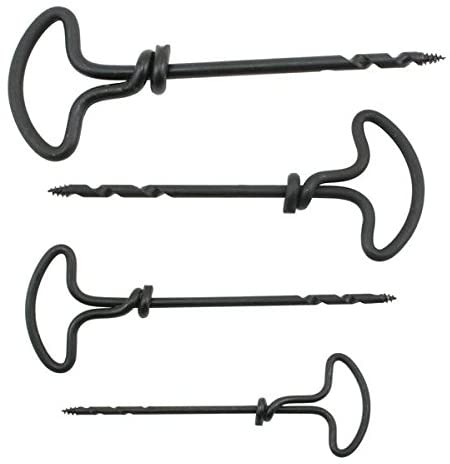

3. Brace Drill

The brace drill has a U-shaped spindle that allows you to generate more torque. It also features another spindle at the top, which allows you to grip and align the tool in the desired position. The brace drill is used for countersinking when working with wood.

4. Bow Drill

The bow drill, also known as a fire drill, can start fires without matches. It has a bow, hearth, spindle, and bearing block. It utilizes friction to create heat, which creates an ember in sawdust.

5. Crank Drill

The crank drill features a high helix angle that allows it to create deep holes in tough materials by increasing its penetration efficiency. It also comes with a sharp tip to enhance its cutting ability. The crank drill is one of the few manual drills to drill into hard metals, such as steel.

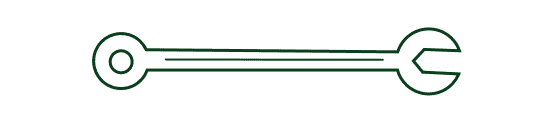

6. Gimlet

A gimlet is a long drill bit that comes with a rotation handle. This tool utilizes leverage to create deep and broad holes. Extending its handles allows you to generate more force.

7. Push Drill

The push drill is a smaller but more powerful version of the hand drill. It features a spiral ratchet for rotating the bit. This drill is used in woodworking applications requiring a higher degree of precision.

8. Post Drill

The post drill is mounted on a durable post. These hand-powered presses can bore holes into iron, but the size and depth of the hole will depend on the operator’s strength.

9. Table Drill

This general-purpose drilling machine provides a wide and stable surface for working on your materials. Nonetheless, since it relies on your strength, it might not be suitable for heavy-duty drilling.

Powered Drills

Powered drills are much more powerful than manual drills but less labor-intensive. As a result, they are ideal for DIYers and professionals. They include:

10. Cordless Drills

Cordless drills are battery-powered, which makes them incredibly convenient since you can use them anywhere. Cordless drills tend to have the least power out of all the powered drill types, but the powerful models are pretty expensive. Another disadvantage of cordless drills is their limited runtime. They are ideal for casual home users or professionals who have to work in off-grid job sites.

Related Article:

11. Corded Drills

Corded drills are lighter and more powerful versions of cordless drills. However, they must be connected to a wall socket to work, which limits their portability significantly. Nonetheless, they are great drills for heavy-duty use in the workshop.

See Also:

12. Reversible Drills

These drills can rotate in clockwise and counterclockwise directions. They are great for tightening and loosening screws quickly and effectively.

13. Impact Drills

Impact drills are well suited for heavy-duty use in woodworking. Unlike standard drills, impact drills start pounding the material once they encounter resistance, thus allowing them to make holes in tougher materials. Nevertheless, they are unsuitable for fastening screws since they jam fasteners into the surface.

14. Hammer Drills

The hammer drill gets its name from its working mechanism, which involves a constant pounding motion. Like impact drills, hammer drills are also terrible at fastening. However, they are excellent at making holes in extra-hard surfaces.

15. Rotary Hammer Drill

This drill is typically used in masonry. It comes with an extra grip for better handling. The main difference between a rotary hammer and a regular hammer drill is that it uses pistons rather than cam plates to accelerate the drill bit.

16. D-Handle Drills

A D-handle drill is essentially a hammer drill with its trigger at the back instead of the front. D-handle drills feature powerful motors that generate constant speed and power. In addition to drilling, they are also used in mixing applications.

17. Combination Drill

Also known as a combi drill, the combination drill can function as an impact and hammer drill. As a result, it is an excellent value for someone who needs both. Combination drills also work on soft and tough materials.

18. Mechanic Drill

A mechanic drill has a versatile design that allows it to adapt to light and heavy-duty use. Therefore, a single mechanic drill should do the trick instead of buying separate drills for softwood and metals.

19. Auger Drill

The auger drill is used to bore holes into the ground. It comes in both one- and two-person versions. The motor is positioned above the bit and comes with large handles.

20. Core Drill

A core drill is handy when making large holes in walls or surfaces. They come with a secondary grip and clutch for better handling and safety.

Pneumatic Drills

Also known as jackhammers, pneumatic drills use compressed air to power their operations. They are incredibly powerful and ideal for heavy-duty use, such as drilling in rocks or breaking up pavement. Some of the types of pneumatic drills include:

21. Straight Air Drills

Straight air drills feature a compact frame, making them ideal for tight spaces. Moreover, they are great alternatives to traditional power drills since they generate more power despite being smaller.

22. Gun Handle Drill

Gun handle drills are even more powerful than straight air drills and are best for industrial applications. They are the most common type of corded drills.

Heavy-Duty Drills

If you run a workshop that performs heavy-duty drilling constantly, a drill press is your best option since they are large and powerful. Some include:

23. Portable Drill Press

Also known as a benchtop drill press, it has smaller proportions than standard drill presses, making it a good choice for DIYers. However, it can hold its own in an industrial setting.

24. Floor Drill Press

This is a larger and more powerful version of the benchtop drill press. The floor drill press is ideal for drilling long and dense objects.

25. CNC Drill Press

This multifunctional machine can drill, bore, mill, and turn. Since it is programmable, the CNC drill press is used in mass-production factories to create precise holes.

26. Mill Drill

This drill press also operates as a milling machine. It resembles a heavy-duty drill press, but it has a larger column and comes with an X-Y table. Therefore, in addition to boring holes, it also removes material. This makes them one of the most versatile tools in a machinist’s workshop.

27. Paper Drill

As its name suggests, the paper drill press makes precise holes in paper. Paper drills resemble standard wood drill presses in function and appearance. However, they vary considerably in power.

Specialty Drills

Some drills are designed for specific purposes and are called specialty drills. Here are some excellent examples.

28. Cranial Drill

The cranial drill has been designed to make holes in dense bones. You will not need one if you are not in the medical profession. Neurosurgeons use cranial drills to drill holes into the skull.

29. Dentist Drill

Resembling a ratcheting wrench, the dentist drill sports a long handle, a cylindrical head, and a tiny bit. The unit can achieve insane speeds of up to 250,000 RPM. As you can tell from its name, the dentist uses it to work on your teeth.

30. Mini Drill

The mini drill is a type of hand drill that resembles a precision screwdriver. It is typically used for high-precision hobbies such as watch repairs and jewelry making. Despite the intricate nature of the work they are involved in, they are remarkably easy to use.

Conclusion

Although we’ve examined 30 types of drills, you’re unlikely to use them all. Electric drills and drill presses have generally replaced hand drills, but some crafters still use them for precise work. Most homeowners and casual DIYers benefit from having a cordless or corded drill for minor repairs and small projects.

However, purchasing a drill press is best if you frequently drill holes into various metals and hardwood. An impact or hammer drill is ideal for specialized projects and auto work.

You might also be interested in:

- How Much Does It Cost to Drill a Well?

- Parts of a Drill (Explained with Pictures)

- 4 Best Mini Mills – Top Picks & Reviews

- 5 Best Right Angle Drills

- What Is a Wheel Alignment (And Do I Need One)?

- Why Does My Transmission Fluid Leak When Parked?

- How to Dry Clothes Fast (Top 10 Methods)

Featured Image Credit: Pixabay

Contents